What is a PID controller?

In the world of marine engineering, ensuring stable and efficient operation of critical onboard equipment is essential. One of the most important components in modern automation and control systems is the PID controller. But what is a PID controller, and why is it so vital for marine boilers and other vessel systems?

Understanding PID control

PID control stands for Proportional, Integral, and Derivative – the three parameters that form the basis of the PID control algorithm.

So, what is the PID? In simple terms, it is an advanced feedback control system used to maintain a desired process condition. The controller continuously calculates an error value between a setpoint (the desired value) and a measured process variable, such as steam pressure, temperature, or fuel flow. Based on this error, the PID controller automatically applies corrections to bring the system back to its target value, ensuring consistent and efficient operation.

Where are PID controllers used?

Where are PID controllers used? They are found across many industries – from manufacturing and energy to automation and marine applications.

Onboard vessels, PID controllers are crucial for maintaining stable operation of boilers, incinerators, fuel systems, and heat recovery units. In marine boiler systems, they precisely manage steam pressure, water level, and combustion balance, ensuring safe and efficient performance even under variable load conditions.

Their ability to maintain optimal control helps shipowners reduce fuel consumption, emissions, and downtime, making them indispensable for modern marine systems.

Difference between PID and PI controllers

The difference between PID and PI controllers lies in the inclusion of the derivative term.

- A PID controller includes Proportional, Integral, and Derivative actions, offering faster and more stable responses in dynamic systems such as marine boilers.

- A PI controller, on the other hand, excludes the derivative component, making it simpler and suitable for slower or less complex processes where fine predictive control is not required.

Understanding whether a process benefits most from PID or PI control is key to achieving reliable automation performance onboard.

PID full form controller for marine boilers

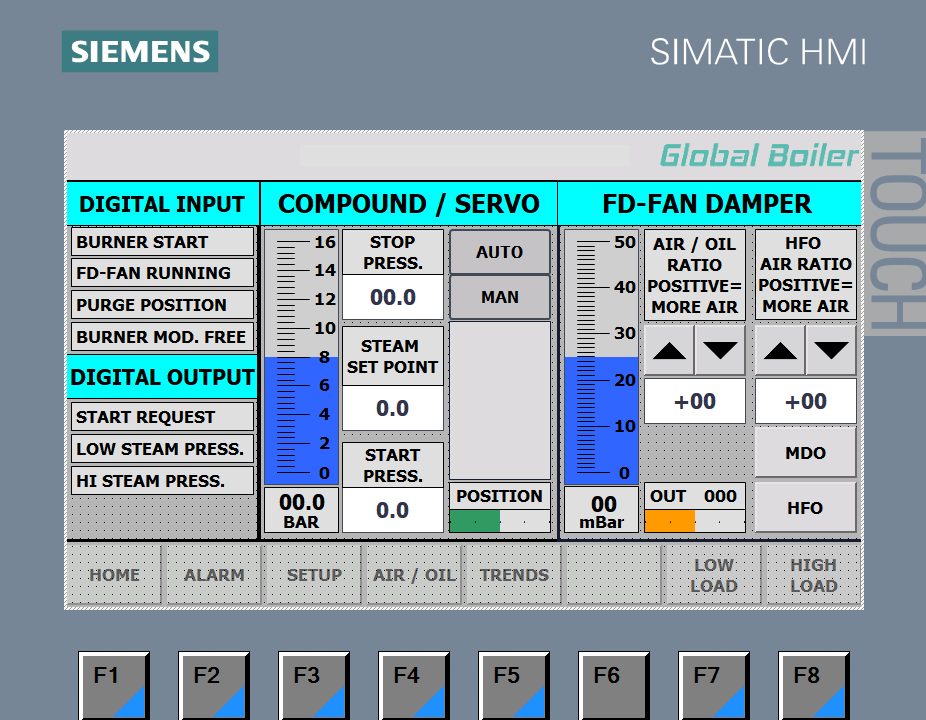

At Global Boiler Services, we specialise in PLC-based PID controllers for marine boilers — advanced systems designed to provide precise, long-term control of combustion and steam parameters.

Our PID full form controller (Proportional-Integral-Derivative controller) is integrated with Siemens PLC hardware, ensuring global component availability and straightforward operation via an intuitive HMI interface.

The benefits include:

- Improved steam stability and combustion efficiency

- Reduced fuel consumption and emissions

- Faster response to load variations

- Enhanced safety and system lifespan

With Class-certified engineers, 24/7 global support, and strategically located hubs in Denmark, Dubai, and Singapore, Global Boiler Services ensures your vessel’s boiler control system remains reliable, compliant, and efficient.

We know your boiler

For more information about PID controllers or to upgrade your marine boiler control system, contact Global Boiler Services today and experience the benefits of smarter automation and reduced downtime.

Contact us for expert advice on PID controllers for marine boilers