AC Drive

An AC Drive, also known as a frequency converter, is a key upgrade for boiler systems featuring separate FD fans (e.g., steam-atomising burners). It enables precise load control and improves energy efficiency via improved turndown ratio.

Why install an AC drive?

Marine boiler plants are typically sized for peak operations like cargo-handling, and with a turndown ratio on approx. 1:5. During sea voyage, the vessel’s steam demand on the AUX boiler drops drastically, and even at minimum load, the AUX boiler capacity is still far beyond steam demand, leading to inefficient start-stop cycles and energy loss.

By installing an AC Drive, Global Boiler Services can reduce your boiler’s minimum load to as low as 5–7% (turn down ratio 1:20) of full steam capacity. This translates to up to 75% reductions in operating costs during periods of low steam demand.

Core benefits of installing an AC Drive for a marine boiler

- Lower Minimum Load: Operate reliably at 5–7% capacity

- Energy & Cost Savings: Reduces fuel usage and operating expenses

- Reduced Power Consumption: Lower start-up current and smoother operation

- Less Wear & Maintenance: Eliminates “air flow hunting”; quieter operation

- Enhanced Combustion at Low Load: More precise air–fuel ratio

- Greener Operation: Energy-efficient, resource-saving technology

How AC drives work

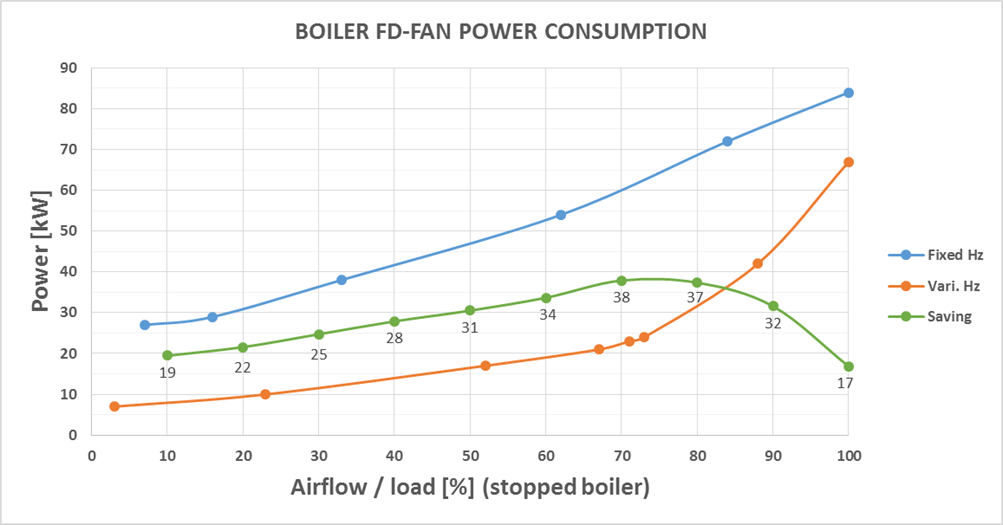

Without an AC Drive, boilers release excess energy every time the system stops and starts, leading to significant resource loss. AC Drives prevent this by adjusting the speed of the FD fan and matching the steam demand with the boiler load. This ensures smoother operation and energy savings.

How it works:

- By controlling the combustion air fan speed, air flow can be adjusted much more precisely at low burner loads.

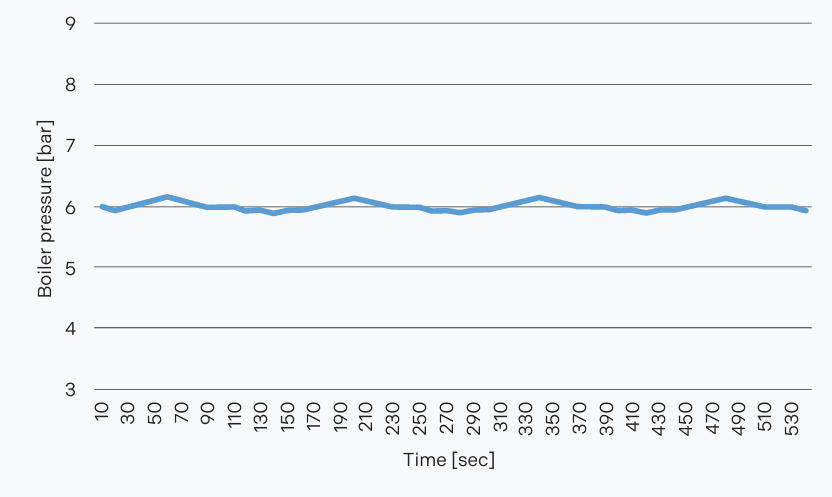

- Creates a more linear boiler pressure curve, reducing spike losses during purge cycles.

- Minimizes start/stop events and stabilizes operation, conserving energy and reducing wear.

Real-world Savings with AC Drives

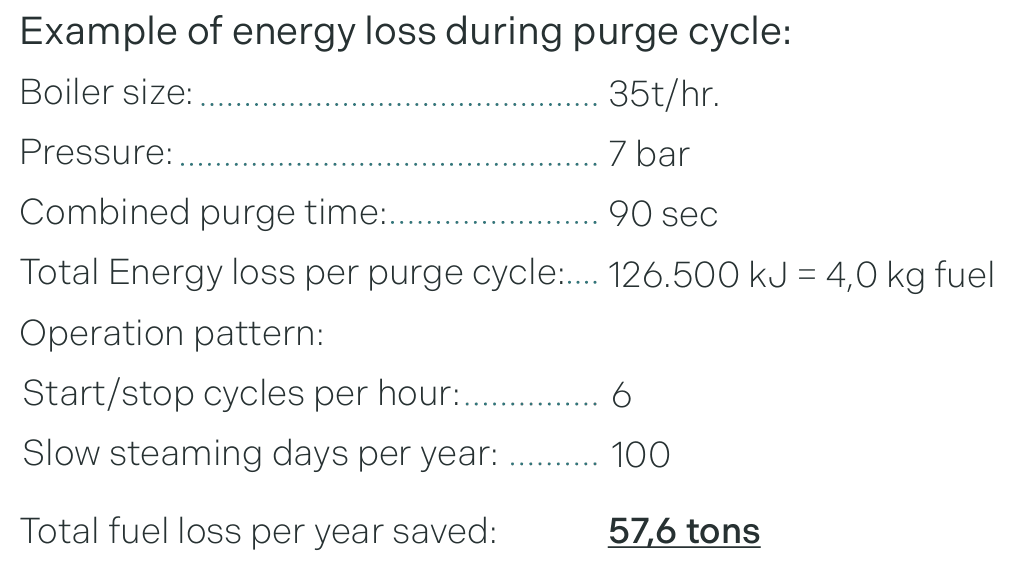

- Boiler capacity: 35 t/h at 7 bars

- Purge duration per cycle: 90 seconds → Energy loss: ~126,500 kJ (~4 kg fuel)

- Typical pattern: 6 start/stop cycles/hour, 100 slow-steaming days/year

- Annual fuel saving: 57.6 tons by avoiding unnecessary purge losses

Installation Process of AC Drive for Marine Boilers

- Initial Assessment

We analyse your boiler system, including FD fan data and motor specifications. - AC Drive Integration

We install and integrate the AC Drive, providing real-time control of combustion air for maximum efficiency. - Optimization

Post-installation, we provide tuning and calibration to ensure optimal performance and longevity of the system.

Request Your Quote Today

To tailor your AC Drive upgrade, we need the following details:

- Annual operating hours and typical load profile

- FD-fan data sheet including motor specs

- Complete wiring diagrams

Send your information to to receive a custom, efficiency-focused proposal or feel free to use our form to contact us today.